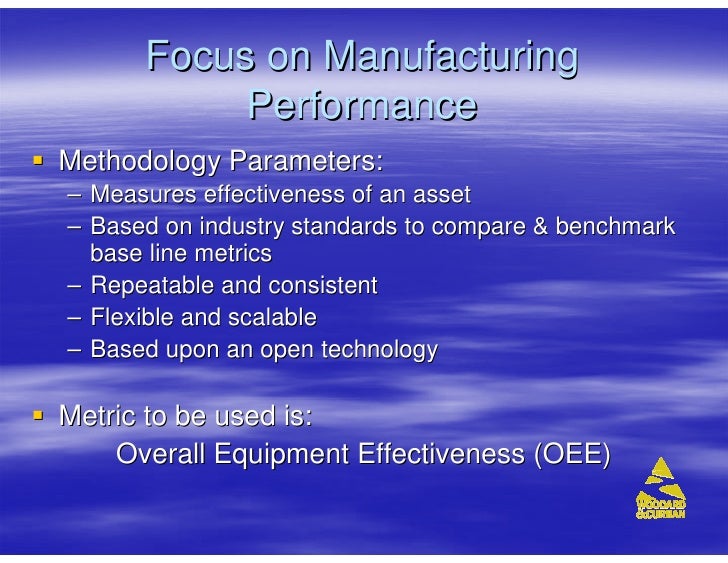

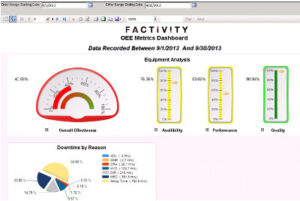

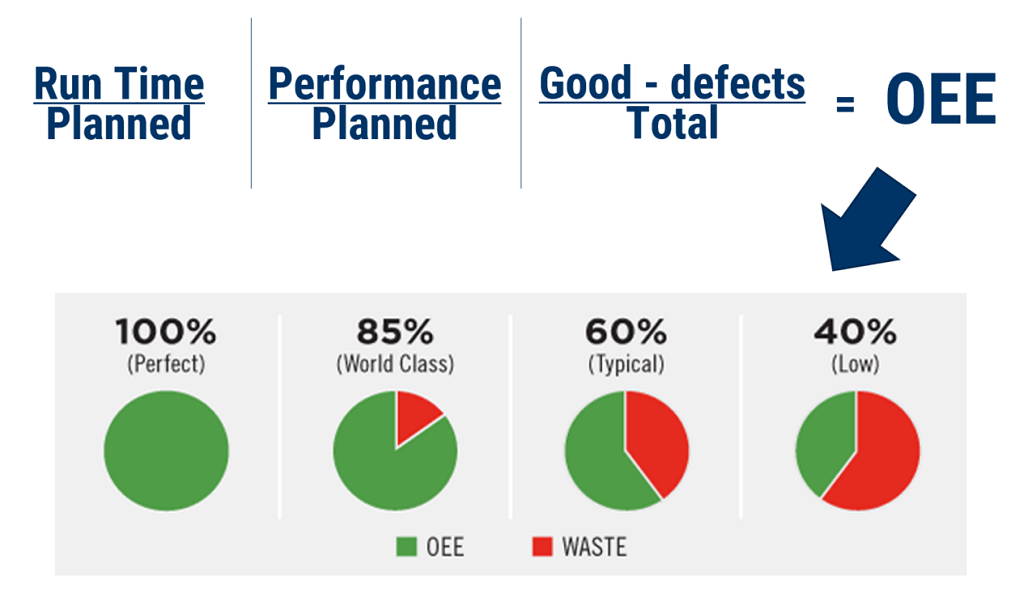

WorldClass Processors of 15 Identified on the basis of 11 metrics from the survey, covering operations, business performance, and human resources Only 21 of 25 worldclass respondents gave permission to use their names • Automation Plastics Corp, Aurora, Ohio • Command Electronics Inc, Schoolcraft, MichA firm's operations are a pivotal element in what customers experience Consumers can say why they like a certain product or service — and why they don't Operations spend company money, interface with customers, and make achieving business goals possible So whatOverall Equipment Effectiveness (OEE) is an analysis of a manufacturer's efficiency and productivity, the results of which are displayed in a hierarchy of metrics Formulated in the 1960s by Seiichi Nakajima, OEE is now globally recognised as a best practice measure and key performance indicator in a range of manufacturing industries – from pharmaceuticals to the automotive industry

Manufacturing Technology What Gets Measured Gets Done

World class manufacturing metrics

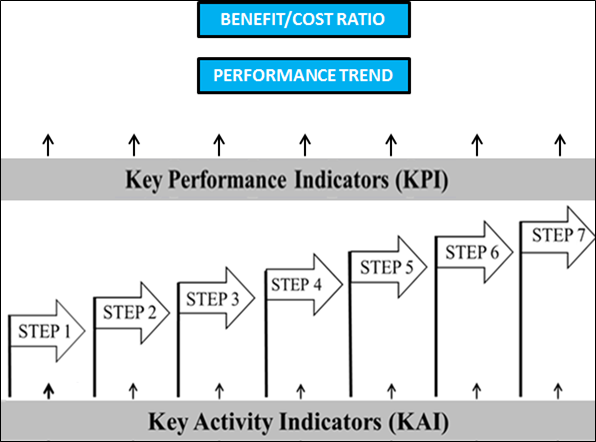

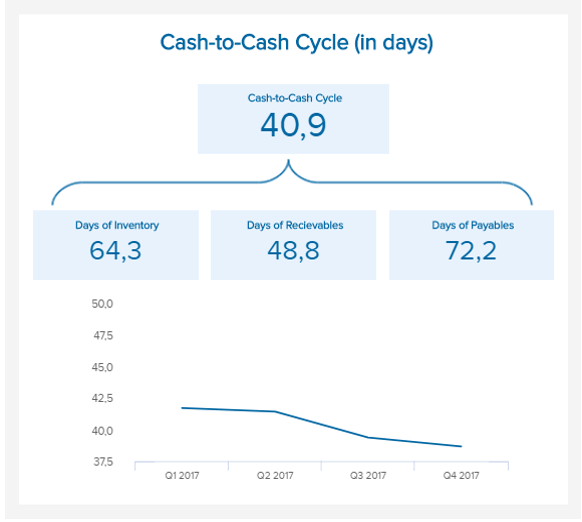

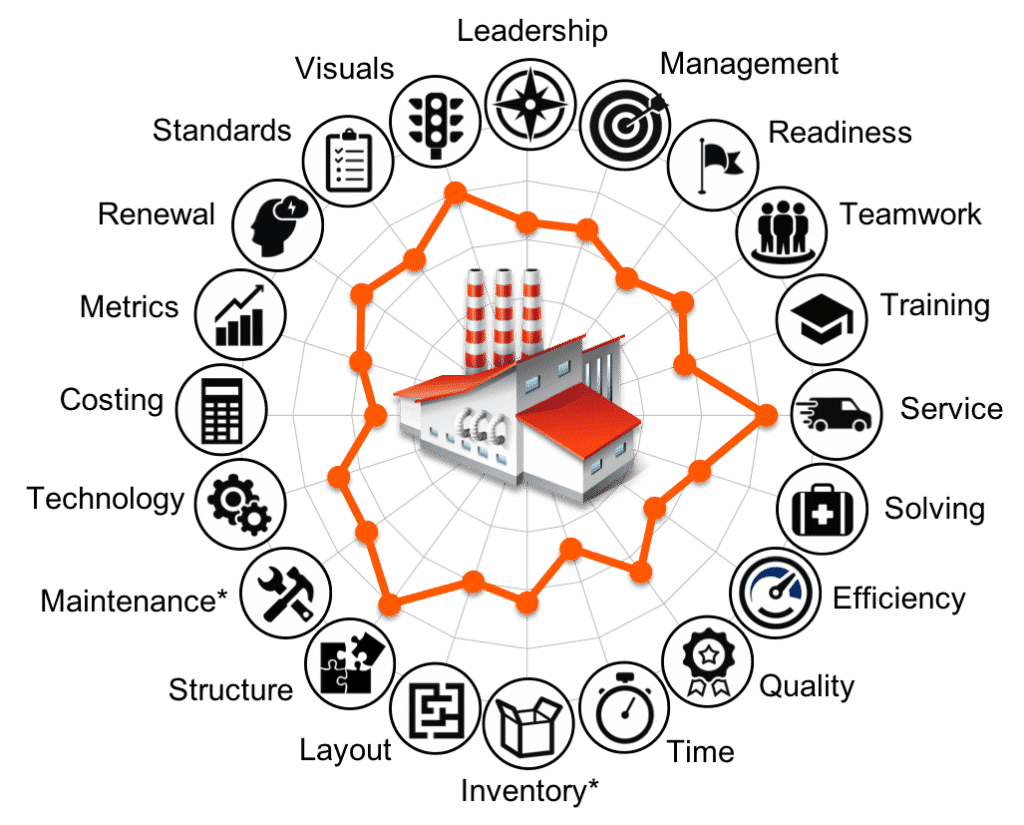

World class manufacturing metrics-Studies on supply chains appear to focus on the effective use of metrics and data World Class companies have an excellent understanding of their endtoend value stream, they understand how theirThe chapter is organized as follows Section 2 introduces World Class Manufacturing and illustrates literature review, mission and principles of WCM, Section 3 describes Tools for WCM with particular attention on their features and on Key Performance and Key Activities Indicators and Section 4 describes the research methodology through a real

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

WorldClass Processors of 15 Identified on the basis of 11 metrics from the survey, covering operations, business performance, and human resources Only 21 of 25 worldclass respondents gave permission to use their names • Automation Plastics Corp, Aurora, Ohio • Command Electronics Inc, Schoolcraft, MichIStock Bottom Line Analytics expertise is a crucial driver enabling smart factories' growth, with ten key metrics essential for keeping the next generation of smart manufacturing centers onEfficiency vs Productivity Metrics that MatterUntil They Don't Posted March 26, 18 Measure efficiency and productivity against your REAL goal I keep seeing the word efficiency in the manufacturing media For s omeone who is a Constraints Management person, this is the equivalent of saying "Ni" to the Knights Who Say Ni (Monty Python reference, okay?) or like scratching your

It is part of the "Overall Equipment Effectiveness" (OEE) metric A production schedule that includes down time for preventative maintenance can accurately predict total productionProduction metrics and Key Performance Indicators (KPIs) are designed to measure the performance of the manufacturing processes and methods to turn raw materials into finished goods and/or services at the enterprise, region, district, and plant levelsThe World Class Manufacturer has a ratio of 70 percent work to 30 percent costadded Quality Costs 4555 Percent Reduction The reduction in the cost of quality by 4555 percent is accomplished through a reduction in appraisal, internal and external failure costs

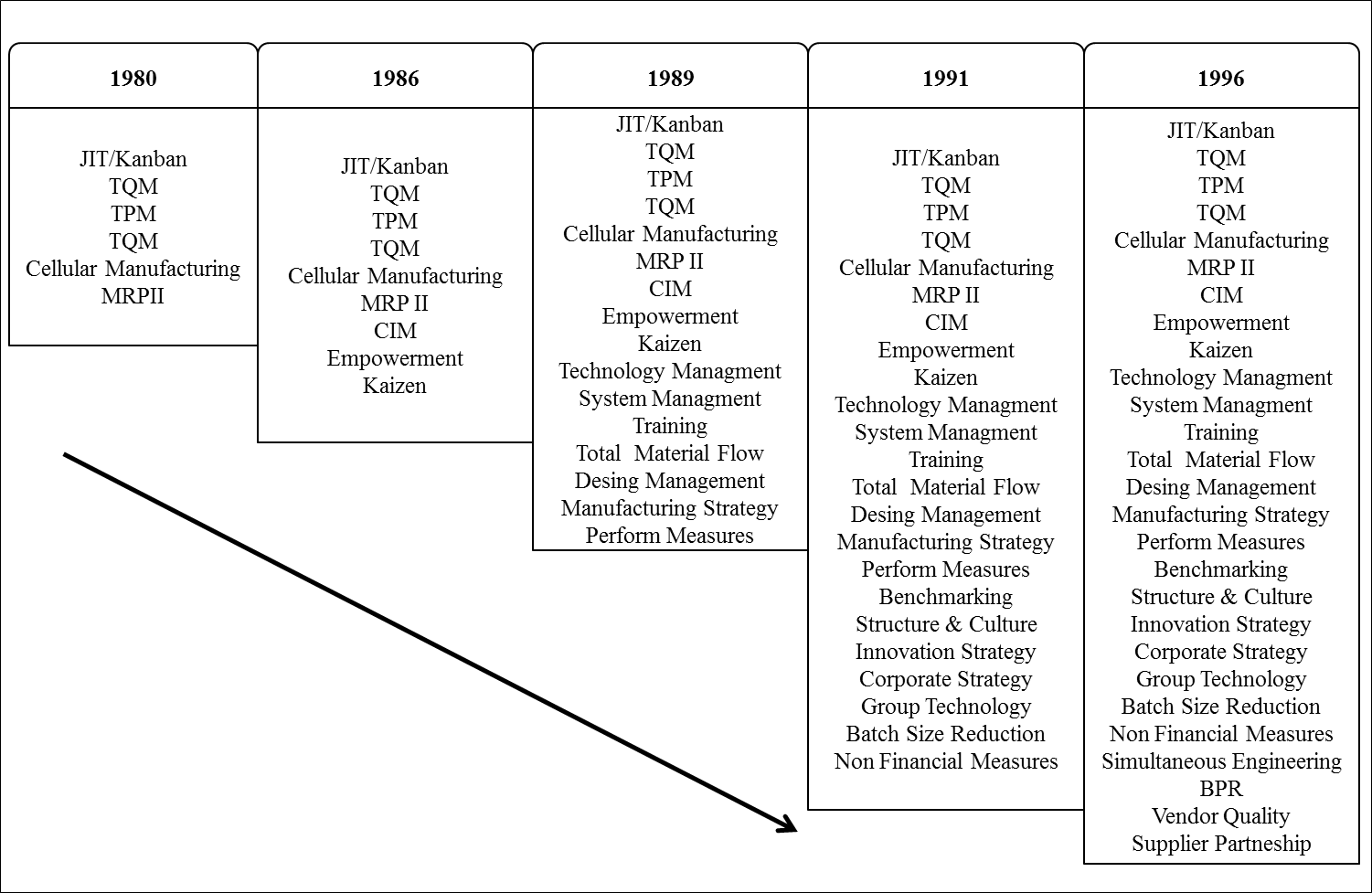

What makes a company world class, or the best at what it does?The companyspecific production system of Chrysler is the World Class Manufacturing (WCM) concept, developed by the Fiat Group in 06But, what exactly is the WCM?Departments In this work is defined a model based on the logical opening of the different pillars that make up the World Class Manufacturing in the Light version, and the definition of appropriate performance indicators that can give a view of the involvement, the management effectiveness and the achievement of objectives

Four Steps To Drive Value From Your Cmms Data Cmms Maintworld

World Class Oee Set Oee Targets To Drive Improvement Oee

Pierre Mitchell of Spend Matters says 10x is an excellent target, though he notes ROI has limitations as a metric especially if investment is low, while the Hackett Group in a 14 report found "worldclass" ROI to be 9x Cost AvoidanceRemember Today, access to your metrics 24/7/365 is really important, what online data analysis tools can guarantee and ensure that your chances of longterm success increase That said, here we're going to look at the top 15 supply chain metrics that will help you, and your business, work toward a bright and prosperous future 1•World Class Manufacturing opens minds and doors to new possibilities It's not always easy Sometimes it's even painfulbut It works!

6 Essential Kpis For World Class Factory Performance

Health And Safety Metrics Dashboard Reporting Kpi Metrics

Worldclass manufacturers are concerned with whether their operations systems have the ability to meet design specifications, rather than with evaluating the quality and quantity of products after the fact In order to attain worldclass status, the manufacturing firm has to be given the proper resourcesHere are the 12 most important metrics to measure in manufacturing that are essential for a successful business Manufacturing cycle time Cycle time is the total time from the beginning to end of a process In manufacturing, it measures the time taken for a product to pass through all machines, processes and cycles to become a finished productWhat makes a company world class, or the best at what it does?

Jamey Heinze First Hand Experience From Morganadvanced On Transforming An Organization Into A World Class Manufacturing Enterprise Through Standardization And Rigor Of Production Systems Build A Common Operational Language Amazing

Towards World Class Manufacturing

1 CustomerFocused Innovation Delivers new and better customer solutions at a faster pace than the competition WorldClass Performance Benchmarks New products as a percentage of total SKUs launched annually>% Percentage of annual sales are derived from products introduced in the past three years Percentage of workforce dedicated to new product development Organization's investment in new product development/R&D as a percentage of sales Is the organization's progress towardManufacturing Cost as a Percentage of Revenue – A ratio of total manufacturing costs to the overall revenues produced by a manufacturing plant or business unit Net Operating Profit – The financial profitability for all investors/shareholders/debt holders, either before or after taxes, for a manufacturing plant or business unitWorld class manufacturing is a collection of concepts, which set standard for production and manufacturing for another organization to follow Japanese manufacturing is credited with pioneer in concept of worldclass manufacturing World class manufacturing was introduced in the automobile, electronic and steel industry

Manufacturing Kpis Metrics Explore The Best Kpi Examples

30 Best Manufacturing Kpis Metrics For 21 Reporting Insightsoftware

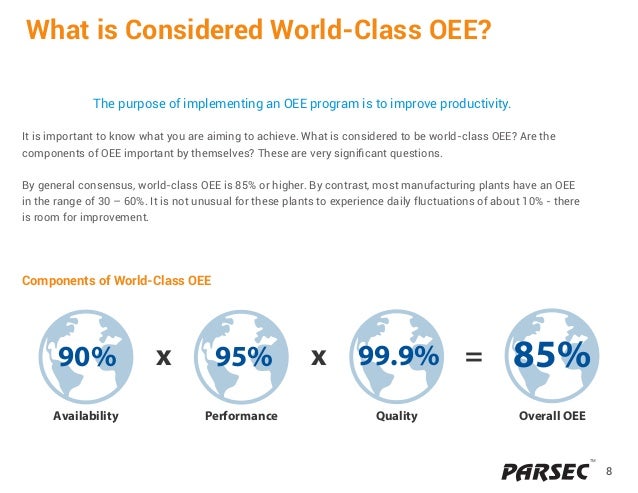

The leading indicators signal future events and the lagging indicators follow the past events The leading indicator comprises from metrics like the Estimated vs actual performance and PM Compliance, while the lagging indicatorare reflected in maintenance metrics like the Mean Time To Repair (MTTR) , Overall Equipment Effectiveness OEE and MeanThe metric that I've used and have been taught for measuring WorldClass manufacturing is OEE, or Overall Equipment Effectiveness The benchmark for WorldClass is 85% OEE (100% OEE means no losses at all) Very few factories in the world are operating at these efficiency levels, hence is why it's regarded as WorldClassMoving toward World Class WCM is a oneway journey / 37

World Class Manufacturing How Do You Measure It Metrics Competition Strategic Management

World Class Manufacturing Asset Utilization

Key performance indicators for the maintenance function, by first looking at the ways that maintenance performance metrics relate to manufacturing metrics Since performance measurements for maintenance must include both results metrics and metrics for the process that produces the results, this document presents a representation for the businessIn other words total indirect & salary divided by total labor (directindirectsalary) I heard 75 to 85 is world class One would think it would vary quite a bit depending on manual intensive the process was, what degree of engineering and office staff were required to support manufacturing (engineer to order) and so forthIn other words total indirect & salary divided by total labor (directindirectsalary) I heard 75 to 85 is world class One would think it would vary quite a bit depending on manual intensive the process was, what degree of engineering and office staff were required to support manufacturing (engineer to order) and so forth

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

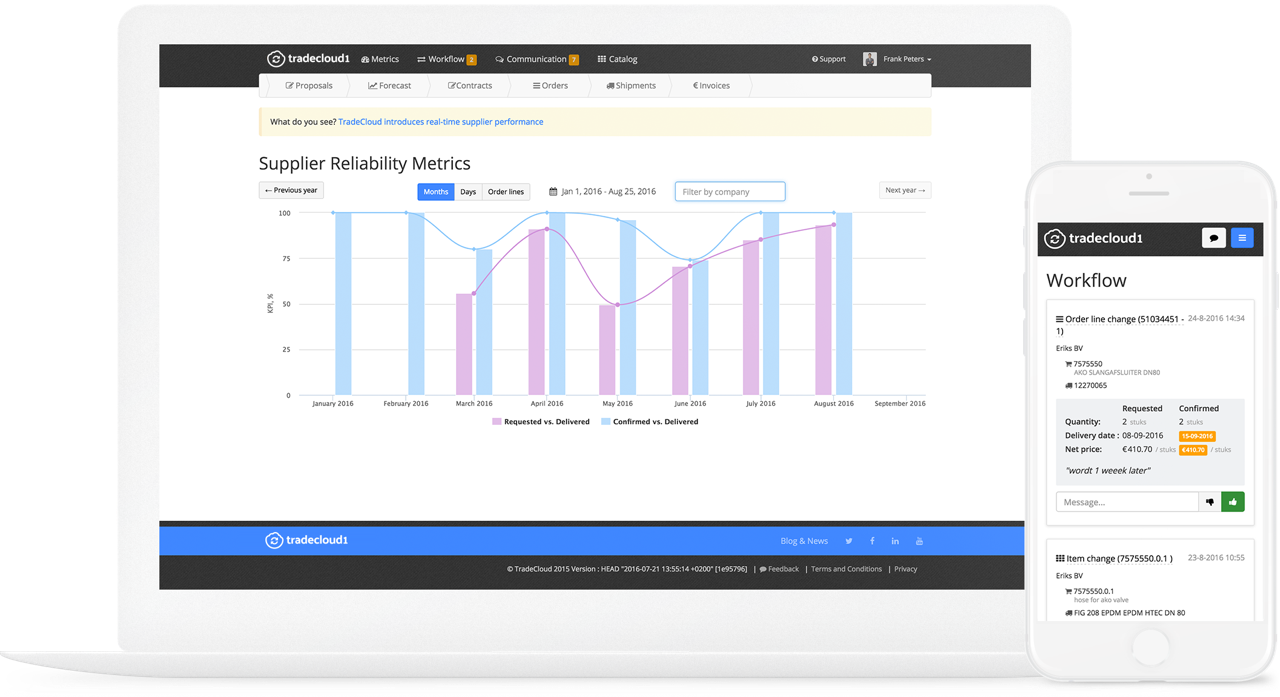

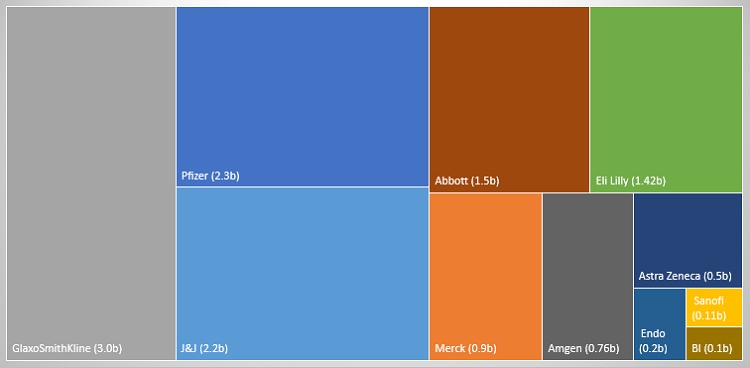

All 17 Key Metrics For Supply Chain Management That You Ever Need Updated Tradecloud

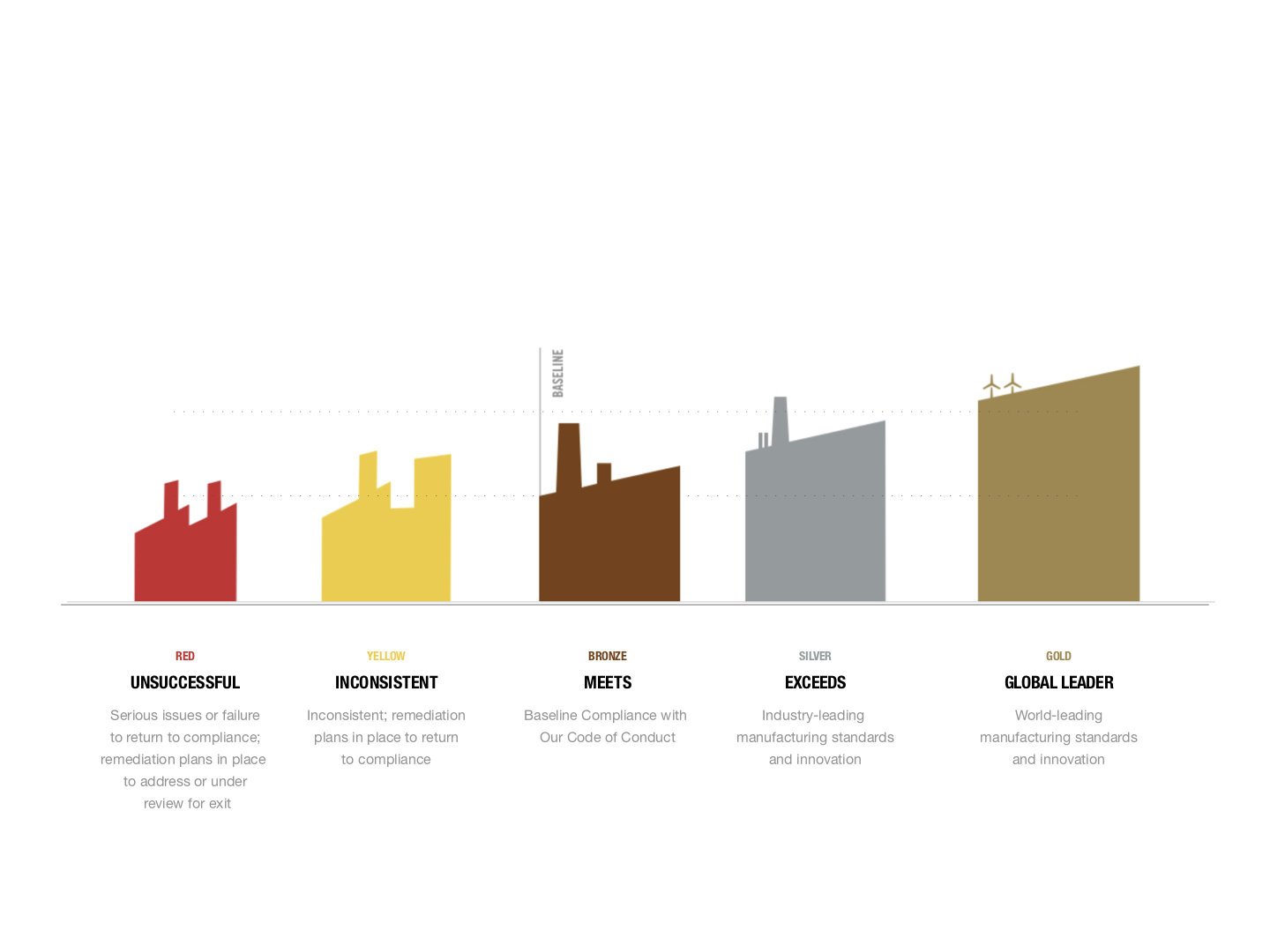

And, what does Chrysler see as keys to success in WCM?The world's most successful manufacturing companies perceive compliance standards as liberating goals to be met and exceeded 5 Key Metrics That Drive Higher Manufacturing Quality Each of the five key metrics reflects how interdependent quality is across manufacturing operations•World Class Manufacturing opens minds and doors to new possibilities It's not always easy Sometimes it's even painfulbut It works!

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Sourcing Standards Nike Purpose

To a degree, worldclass safety is used in a very generic sense, and worldclass performance can be measured in a number of ways, according to Jim Johnson Johnson is the former vice president of workplace safety initiatives for the National Safety Council and current vice president, partnerships, for DEKRA InsightIStock Bottom Line Analytics expertise is a crucial driver enabling smart factories' growth, with ten key metrics essential for keeping the next generation of smart manufacturing centers onIn doing this, ingredients of World Class Manufacturing are reviewed, measurement of company performance is elaborated, hypotheses and research methodology are developed, and data are analysed to

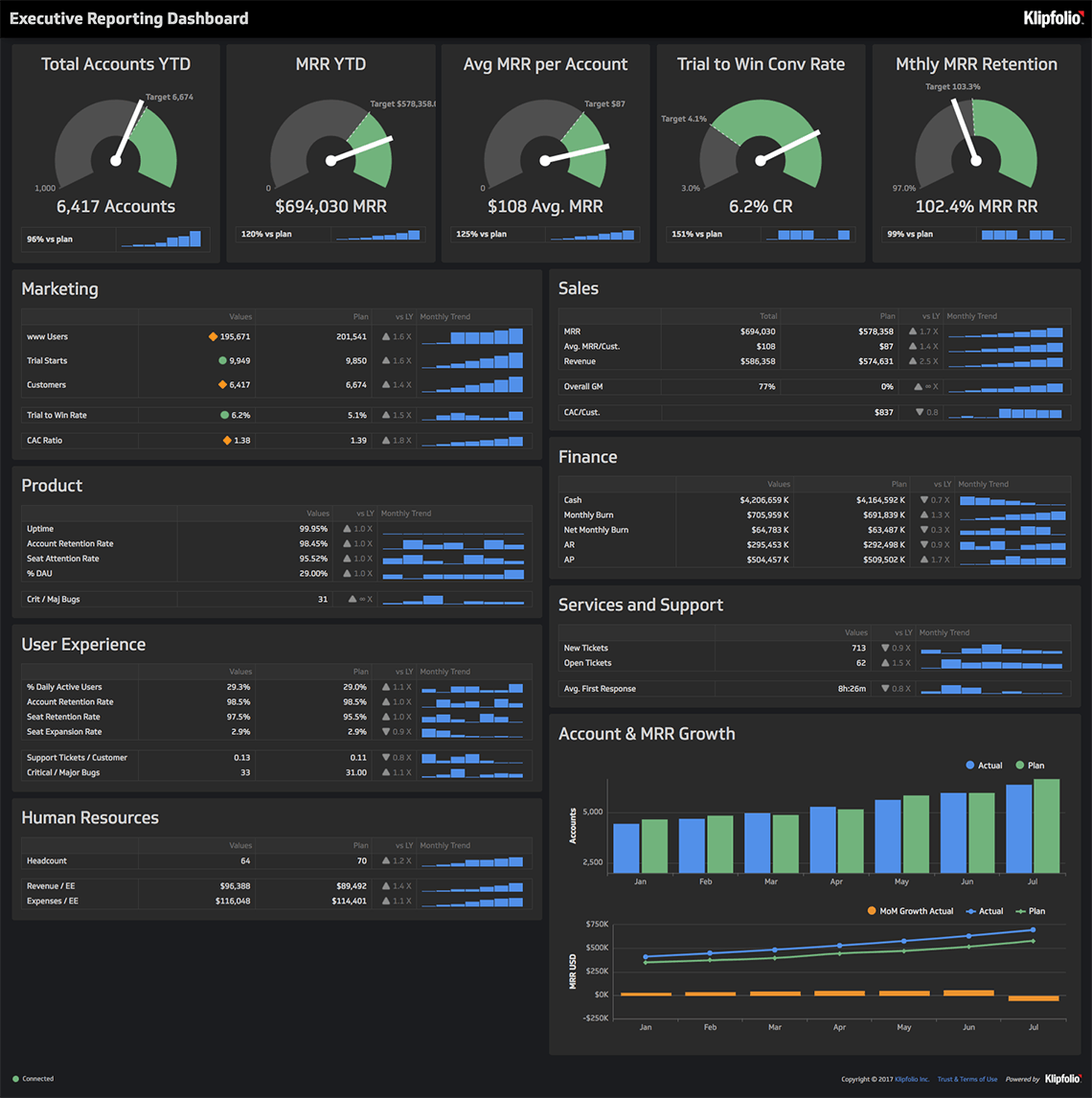

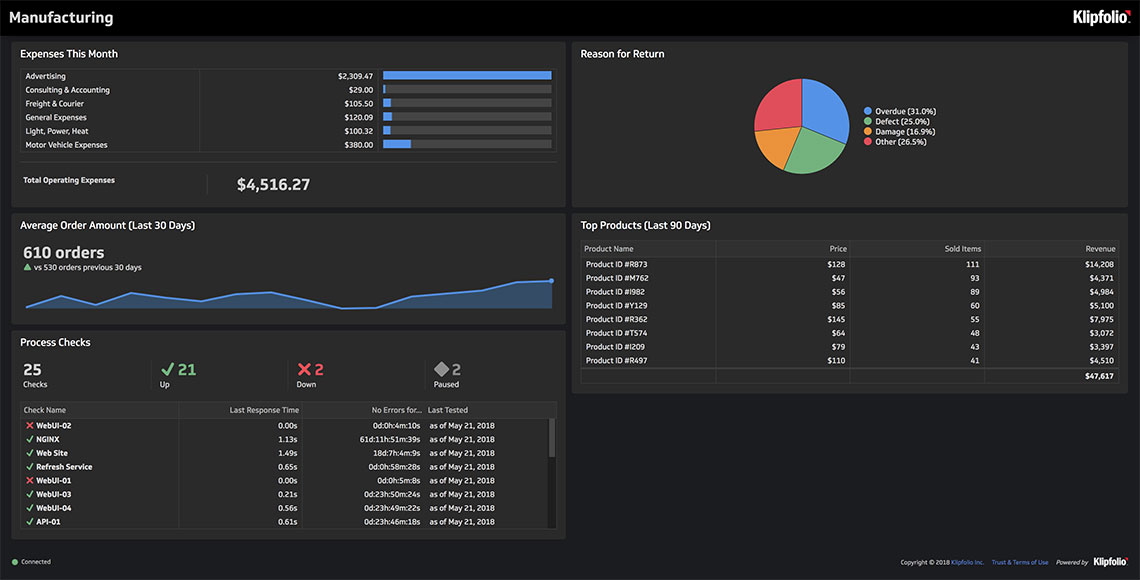

Klipfolio Dashboards And Reports For Manufacturers

Manufacturing Technology What Gets Measured Gets Done

It makes the difference!World class manufacturing is a collection of concepts, which set standard for production and manufacturing for another organization to follow Japanese manufacturing is credited with pioneer in concept of worldclass manufacturing World class manufacturing was introduced in the automobile, electronic and steel industryParts per million defectives is the one metric that companies can look towards for a real understanding of the quality of their products or the lack thereof PPM defectives guide Six Sigma practitioners to improve upon processes until the best possible quality standards can be sustained

Why You Need A World Class Quality Culture And How To Build One

Calculate Teep Measure Utilization And Capacity Oee

World Class Performance Metrics Maintenance & Metrics Manufacturing industry is primed to digitalize Industrial machine alignment Tips for getting precise measurements in demanding conditions Pandemic or not, digital transformation of maintenance workflows is moving forwardMeasuring OEE is a manufacturing best practice By measuring OEE and the underlying losses, you will gain important insights on how to systematically improve your manufacturing process OEE is the single best metric for identifying losses, benchmarking progress, and improving the productivity of manufacturing equipment (ie, eliminating waste)As part of the most recent metrics survey, 28 manufacturing metrics were identified as being the most utilized by discrete, process, and hybrid/batch manufacturers Below, we've grouped these metrics with the associated toplevel area of improvement/goal for each Improving Customer Experience & Responsiveness

Klipfolio Dashboards And Reports For Manufacturers

World Class Manufacturing Information And Free Guides

It makes the difference!Manufacturing Media Five Steps To Build World Class KPIs and many of us readily recognize the importance of key performance indicators (KPIs) and metrics In my career, I have oftenSome Perspective The WorldClass OEE figures are interesting and useful, but keep in mind that they have roots in a particular place (Japan), at a particular time (1970s), and in a particular industry (automotive) The reality is that most manufacturing companies, even today, have OEE scores closer to 60% We work with thousands of manufacturing companies, and we see more companies with OEE

28 Manufacturing Metrics That Actually Matter The Ones We Rely On

Defining Lean 16 Must Have Metrics For Any Lean Supply Chain

An excellent metric for determining how strong collaboration is in a manufacturing operation, demand forecast accuracy reflects the variation in real or actual demand and what is forecasted at the factory level Inventory metrics for manufacturing can make operations more effective by closing the gaps between forecasted demand and actual demandIt changed the way we do business!Here are our "top six" essential manufacturing KPIs to get you started 1 Overall equipment effectiveness (OEE) OEE is a much talked about KPI and shows how manufacturing assets perform relative to their theoretical maximum potential Businesses that invest heavily in plant will find that OEE measurement is an essential metric to track

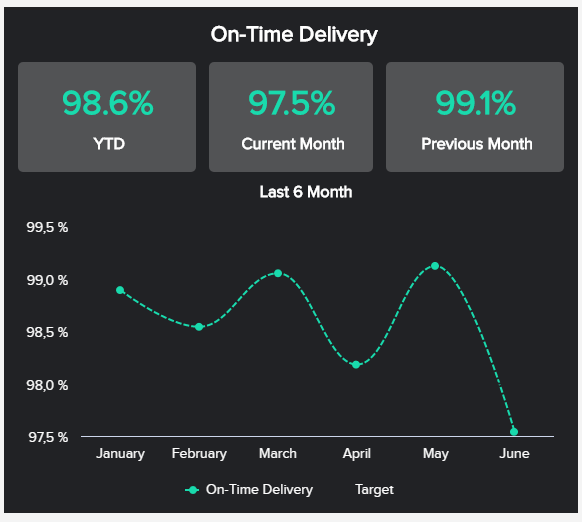

Better On Time Delivery Using Metrics To Improve The Production Process Part 1 Factivity

World Class Manufacturing

"Availability" is a key performance indicator in manufacturing;A firm's operations are a pivotal element in what customers experience Consumers can say why they like a certain product or service — and why they don't Operations spend company money, interface with customers, and make achieving business goals possible So whatIt changed the way we do business!

6 Essential Kpis For World Class Factory Performance

Top Inventory Management Metrics Inventory Kpis For 21

Manufacturing KPIs can highlight progress towards goals set at various levels of a company Together, the sum of these KPIs tells a story about the performance of the line, plant, and/or company The goal of this post is to explain how to calculate 34 manufacturing KPIs 1 Asset utilization is a metric used to understand efficiency ToManufacturing Cost as a Percentage of Revenue – A ratio of total manufacturing costs to the overall revenues produced by a manufacturing plant or business unit Net Operating Profit – The financial profitability for all investors/shareholders/debt holders, either before or after taxes, for a manufacturing plant or business unitManufacturing KPIs can highlight progress towards goals set at various levels of a company Together, the sum of these KPIs tells a story about the performance of the line, plant, and/or company The goal of this post is to explain how to calculate 34 manufacturing KPIs 1 Asset utilization is a metric used to understand efficiency To

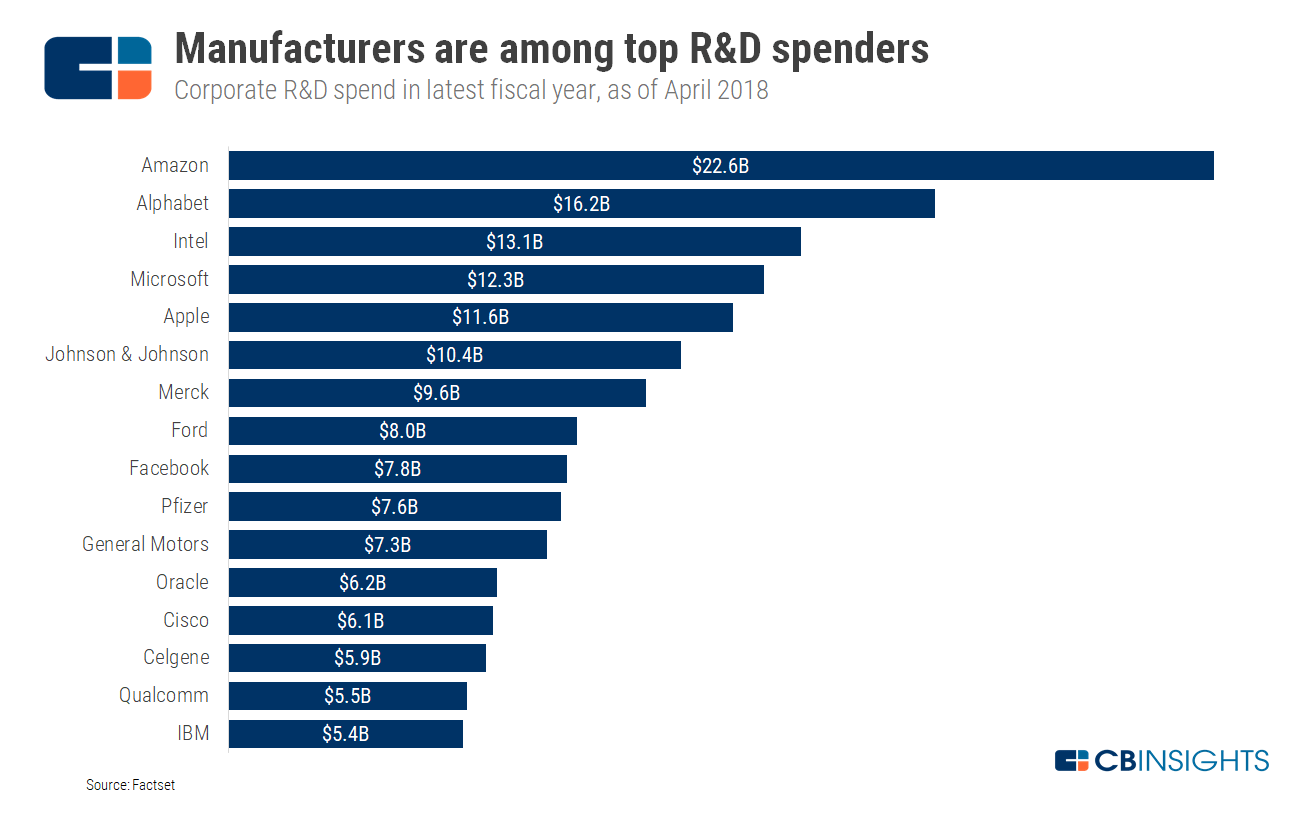

The Future Of Manufacturing Technology L Cb Insights

30 Best Manufacturing Kpis Metrics For 21 Reporting Insightsoftware

Moving toward World Class WCM is a oneway journey / 37World Class Manufacturing PM – Machine Ledger and PM Calendar Planned Maintenance TPM World Class Manufacturing February 27, 0 1,295 Prioritizing the Equipment and Selecting the Maintenance System Blog December 23, 18 0 902 Breakdown Recurrence Matrix Blog Quality Training June 3, 18Departments In this work is defined a model based on the logical opening of the different pillars that make up the World Class Manufacturing in the Light version, and the definition of appropriate performance indicators that can give a view of the involvement, the management effectiveness and the achievement of objectives

Health And Safety Metrics Dashboard Reporting Kpi Metrics

Supply Chain Key Performance Indicators Tips To Get Them Right

A few answers are given these days at the 4th annual Lean Management Journal Conference in Birmingham, UK in his morning keynote, Mauro Pino—Vice President for vehicleWorld Class Manufacturing PM – Machine Ledger and PM Calendar Planned Maintenance TPM World Class Manufacturing February 27, 0 1,295 Prioritizing the Equipment and Selecting the Maintenance System Blog December 23, 18 0 902 Breakdown Recurrence Matrix Blog Quality Training June 3, 18

The Future Of Manufacturing Technology L Cb Insights

Customer Service Metrics Top 10 You Must Measure Qualtrics

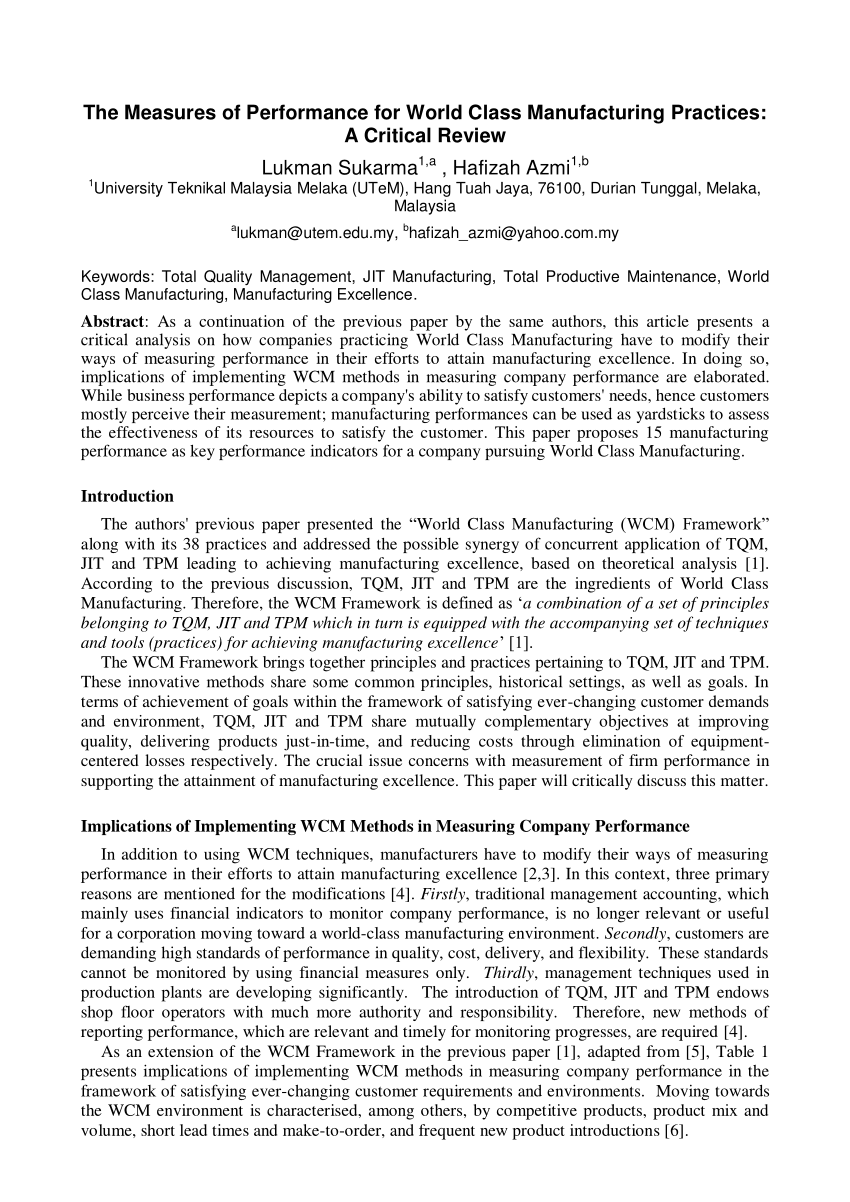

Pdf The Measures Of Performance For World Class Manufacturing Practices A Critical Review

World Class Manufacturing Kerala Univ Mba Mod 1

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

In A World Class Manufacturing One Of The Metrics Of High Impact Is The Oee And It Is The Main Metric To I Lean Manufacturing Change Management Lean Six Sigma

Challenge To World Class Manufacturing

In A World Class Manufacturing One Of The Metrics Of High Impact Is The Oee And It Is The Main Metric To Im Lean Manufacturing Lean Six Sigma Change Management

21 Manufacturing Kpis And Metrics Updated For 21 To Improve Production Kpi Performance

Masters In Lean Manufacturing Degree Online Kettering University

10 Steps To An Effective Manufacturing Operations Management Strategy

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Infographic Operational Performance Excellence Operations Management Management Leadership Management

World Class Manufacturing

Sourcing Standards Nike Purpose

Measurement Systems Analysis Is A Key To World Class Manufacturing Ee Times

Optimize Manufacturing Operations With 5 Golden Metrics

Kaizen Six Sigma Lean Management Training Consulting Operational Excellence Global Leader Pioneer In Kaizen Lean Operational Excellence Domain Page 16

World Class Manufacturing

The Value Of Learning Consortia For Achieving Performance Excellence In Manufacturing Ivey Business Journal

28 Manufacturing Metrics That Actually Matter The Ones We Rely On

6 Essential Kpis For World Class Factory Performance

Xerox 14 Report On Global Citizenship

The Keys To World Class Manufacturing Emaint Cmms

World Class Manufacturing Archives Business Building Information

Overall Equipment Effectiveness Oee An Overview Reliable Plant

The Keys To World Class Manufacturing Emaint Cmms

Make Better Business Decisions Using Product Manager Kpis Toptal

Manufacturing Kpis Metrics Explore The Best Kpi Examples

World Class Manufacturing Information And Free Guides

World Class Oee Software By Sage Clarity

The Top 15 Supply Chain Metrics Kpis For Your Dashboards

World Class Manufacturing

30 Best Manufacturing Kpis Metrics For 21 Reporting Insightsoftware

What Is World Class Manufacturing And How Do You Measure It Industryweek

Oee Measures Improvements In Productivity Lean Production

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Top Inventory Management Metrics Inventory Kpis For 21

Halo Metrics

Top 12 Manufacturing Kpis To Track Operational Excellence Sensrtrx Manufacturing Analytics

World Class Manufacturing The Next Decade Building Power Strength And Value Schonberger Richard J Amazon Com Books

Why Is World Class Oee A Myth Sensrtrx Manufacturing Analytics

The Measures Of Performance For World Class Manufacturing Practices A Critical Review Scientific Net

Great Read Honda S Obsession With Metrics Industryweek Excellence Metrics World Honda S Whirlpool

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Focus Improvement On The Manufacturing Constraint Lean Production

World Class Manufacturing How Do You Measure It Metrics Competition Strategic Management

Manufacturing Strategy And The Concept Of World Class Manufacturing Emerald Insight

World Class Manufacturing

30 Best Manufacturing Kpis Metrics For 21 Reporting Insightsoftware

11 Trends That Will Dominate Manufacturing In 21

In A World Class Manufacturing One Of The Metrics Of High Impact Is The Oee And It Is The Main Metric To Improve At Tpm Deployment Start Up Metric Deployment

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Oee Measures Improvements In Productivity Lean Production

Becoming A World Class Quality Organization 16 05 01 Quality Magazine

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

World Class Manufacturing Home Page

Klipfolio Dashboards And Reports For Manufacturers

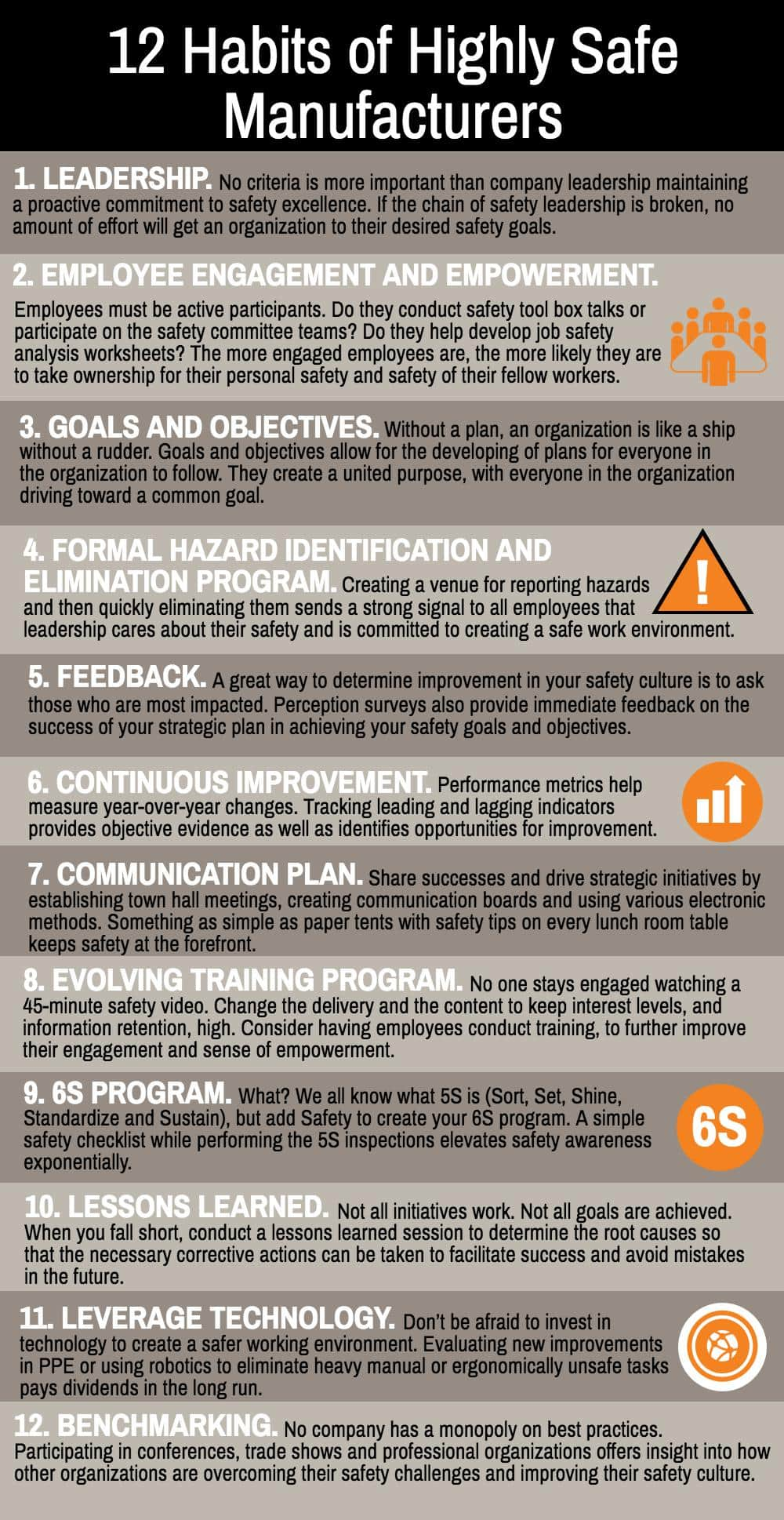

Habits Of Safe Manufacturers Victaulic

Performance Measurement For World Class Manufacturing A Model For American Companies Hardcover Brian H Maskell Amazon Com Books

In A World Class Manufacturing One Of The Metrics Of High Impact Is The Oee And It Is The Main Metr Lean Manufacturing Operations Management Change Management

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

The Critical Kpi To Drive Manufacturing Productivity

Full Article Performance Measurement For World Class Manufacturing A Model For The Italian Automotive Industry

Lean Audit Operations Diagnostics Book Leanmap

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Halo Metrics

0 件のコメント:

コメントを投稿